SUSTAINABILITY

Transparency Act

Statement in accordance with the Transparency Act

Act relating to enterprises' transparency and work on fundamental human rights and decent working conditions (Transparency Act)

Norway, Drammen, 2025-05-12

Fell Tech's Work on Human Rights and Ethical Trade Introduction

Introduction

Fell Tech's mission is to build sustainable societies for generations, and our vision is to serve as a climate role model. Our values oblige us to adhere to the highest ethical standards and conduct business in a responsible and sustainable manner. This commitment is reflected in everything we do. It's also an ongoing process, where there is always a need and room for continual improvements. Fell Tech aims to be a pioneering company in terms of responsible and sustainable operations, while also supporting larger collaborations in the industry to address common challenges related to this work.

The technology industry, including electronics, has several risk elements related to both working conditions in Norway and Europe, and the conditions under which products and components are produced in Eastern Europe and Asia.

In this memorandum, we outline the company's efforts in due diligence related to human rights, decent working conditions, and ethical trade in line with the requirements of the transparency law.

Anchoring Accountability

Fell Tech's Supplier Integrity Guide ensures that our values and ethical guidelines are integrated across all companies within the Fell Tech group. Fell Tech imposes the same requirements on our suppliers and their subcontractors. The Supplier Integrity Guide applies to all companies supplying products and/or services to Fell Tech. In 2023, Fell Tech introduced a corporate policy on human rights, with follow-up measures to ensure that human rights and labor law requirements are met. Risks identified through due diligence, as well as entry into new business areas, are expected to set new requirements for the content of the company's policies. This will be assessed as part of our ongoing work towards continuous improvement. We continuously work to anchor the requirements of the code of conduct and policy in our operations, including through training in the code of conduct and by including considerations of human rights and decent working conditions in our internal routines and guidelines.

Due Diligence/Risk Assessments

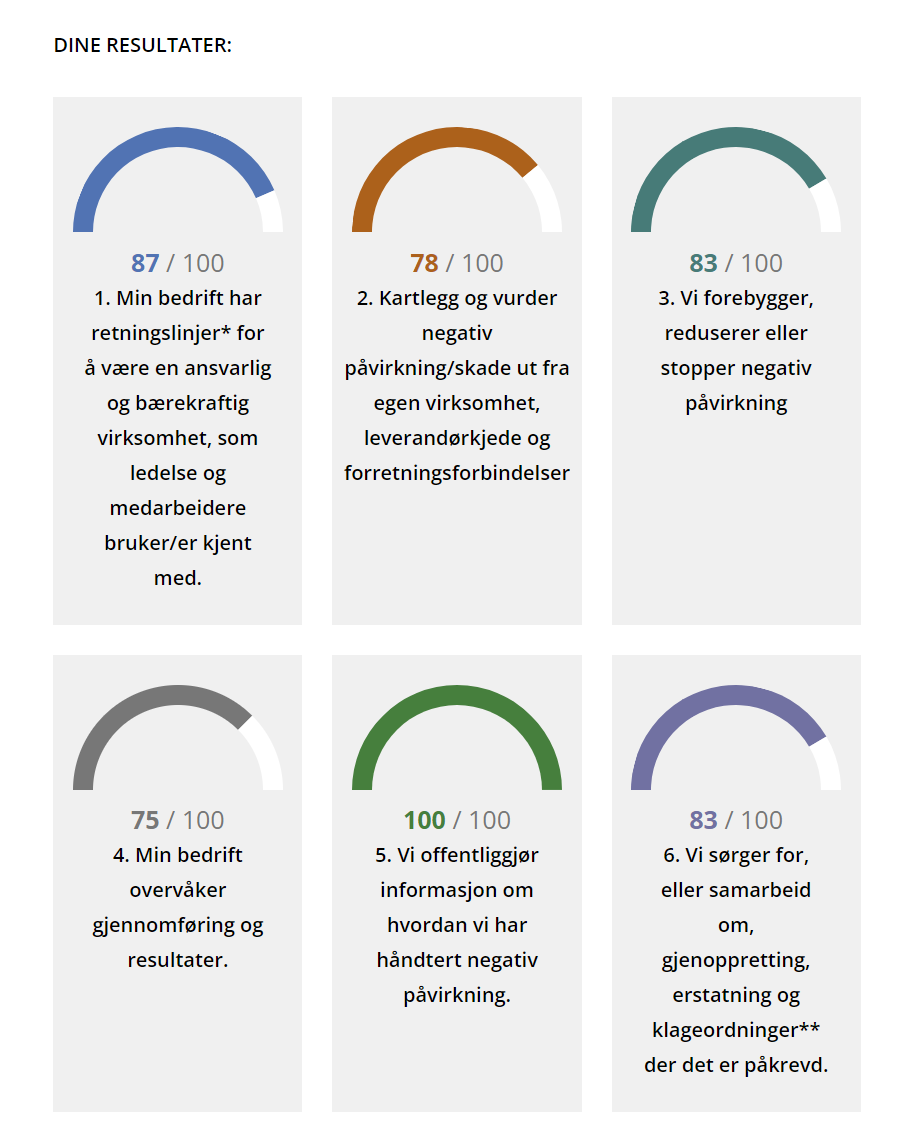

The purchasing process and risk assessments of suppliers are crucial in our efforts to promote respect for fundamental human rights and decent working conditions. Fell Tech is aware that there are risk products where irregularities may occur in our value chain, and our ongoing work with risk mapping and supplier evaluation commenced in 2019. We base our work on the OECD's Due Diligence Guidance for Responsible Business Conduct, and use the OECD's National Contact Point self-test1 to evaluate our ongoing work.

Results in Norwegian. Link to self assessment tool: https://www.responsiblebusiness.no/egentest-aktsomhetsvurderinger/

Fell Tech uses a Supplier Survey via our own ERP system to send out and analyze our supplier portfolio. Fell Tech's largest suppliers are connected to the system and receive requests to provide information on the following topics:

- Corporate information (products, countries, employees, subcontractors)

- Finance

- Quality management

- Environmental management

- Social responsibility/human rights

- Work environment/HSE

- Conflict minerals

- Signed Fell Tech's Integrity Guide for suppliers

Companies are assigned a risk score based on Fell Tech's assessments of the responses, as well as system-generated risk scores based on the countries where the company, production, and subcontractors are located. The process is under development and improvement, so that companies' risk scores over time will be better calibrated and more accurate. The company's risk score in the system, along with results from information gathering for supplier prequalification, provides the company with a rating from low to high, which will eventually be published in the internal supplier registry. Currently, this link is made manually, and there is a plan to automate this process in the future to ensure the availability of updated data when making purchasing decisions.

Our efforts to map and assess negative impact and damage in our value chain are based on the company's main process for core activities in service and contracting. Both risks related to our own operations and the supplier chain have been assessed based on actual reporting, while risk assessments related to the value chain beyond the first and second supplier tiers are based on desktop research.

Information on the use of materials and the composition of specific products is based on environmental analyses of all components and their data sheets through systems like SiliconExpert and similar, specification requirements to manufacturers and suppliers, and requirements for certificates of conformity to the same specifications. Products in the construction sector have been developed with Environmental Product Declarations (EPDs) from 2024, such as the Waterguard product series.

In the following areas, particular risks associated with Fell Tech's direct or indirect influence through our business and value chain have been identified:

- Conflict minerals

- Transport

- Labor and employment conditions at suppliers and manufacturers

- Technology components

Fell Tech has a complex value chain, with many links and suppliers. This is a risk in itself as it makes it more challenging to maintain a comprehensive overview of the flow of materials, goods, and services. Fell Tech's established electronics sector is a risk area due to the materials used in the products and components. This primarily relates to metals and minerals that carry a higher risk of human rights violations. The use of labor, both in our own operations and in the form of subcontractors, is an area where there is a risk of potential violations of basic worker rights, decent working conditions, health and safety considerations, and workplace equality.

Transport is a significant risk area because Fell Tech's supply chain is global and consists of many links, with materials, components, and finished products needing to cross national borders. This is also an area that Fell Tech has yet to thoroughly map and document, as many suppliers serve as subcontractors to our electronics production partners. In 2023, we are working on Life Cycle Assessment (LCA) mapping for all products being produced, and the majority of our product portfolio is primarily manufactured in the Nordic region.

Moving forward, Fell Tech will implement the EcoVadis system to better enable actionable risk management solutions, assist in meeting compliance requirements, and implement our company's sustainability strategy.

Follow-up of our product and material suppliers and measures to reduce risk

Since the company's largest suppliers are production partners that purchase components from wholesalers with a considerable number of subcontractors, it is assessed that the highest general risk lies in this portion of the supplier portfolio. Since 2024, a more extensive supplier review (due diligence) of the company's largest suppliers and subcontractors based on turnover to Fell Tech is being carried out. This is facilitated through the work on Life Cycle Assessment (LCA) mapping for new products. Fell Tech is on track with its long-term goal of conducting similar supplier reviews (due diligence) for all suppliers by 2025 with a special focus on human rights in accordance with new legal requirements. Better data will enable a more accurate and risk-based method of supplier review.

All contracts/agreements should include a requirement for the supplier's self-declaration and signing of Fell Tech's Supplier Integrity Guide for suppliers, and all Purchase Orders include a reference to Terms and Conditions for Purchase that require the suppliers to comply with the Supplier Integrity Guide by delivering goods and services to Fell Tech against Purchase Orders. To ensure the integrity of these terms and conditions, Fell Tech has implemented a No-PO, No-Pay policy to ensure purchases are only made through the company's official Purchase Orders using the approved terms and conditions and Supplier Integrity Guidelines.

Identified measures within Fell Tech include:

- Policy for materials

- Increased dialogue with the manufacturing sector about their role in the value chain

- Training in the company's work with human rights for all purchasing boards

- Reporting and disclosure of information

The corporate management group in Fell Tech Norway has carried out the initial due diligence and risk assessments. The Business Operations unit and the Product Development & Engineering unit are responsible for follow-up, vendor quality assessments, and tests of suppliers.

From 2025, Fell Tech will report on the company's work with human rights as part of the group's ESG reporting. The annual and sustainability report for 2025 will for the first time include a statement in accordance with the requirements of the transparency law, including our work with due diligence and follow-up of human rights and decent working conditions in our operations and value chain.

Inquiries and questions related to Fell Tech's work with human rights and decent working conditions can be directed to [email protected] and will be answered within three weeks of the inquiry being received.